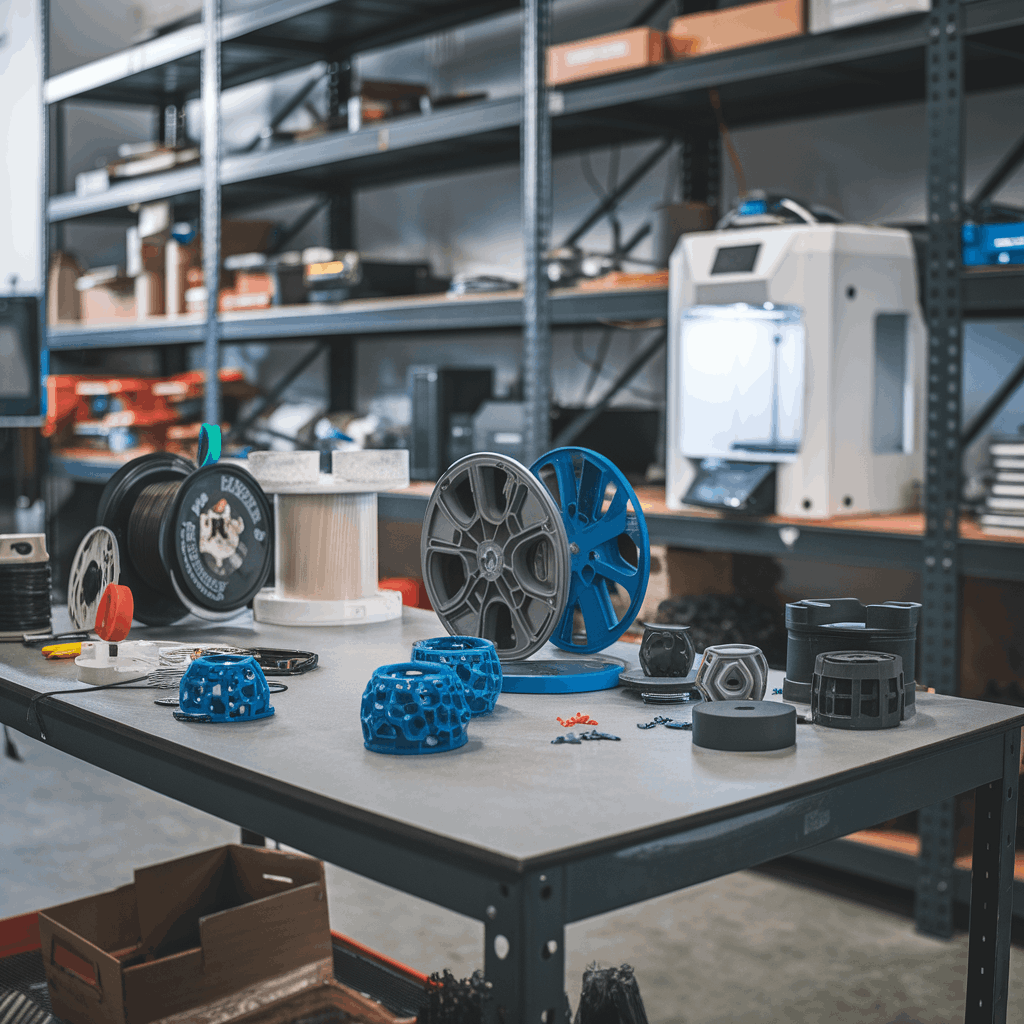

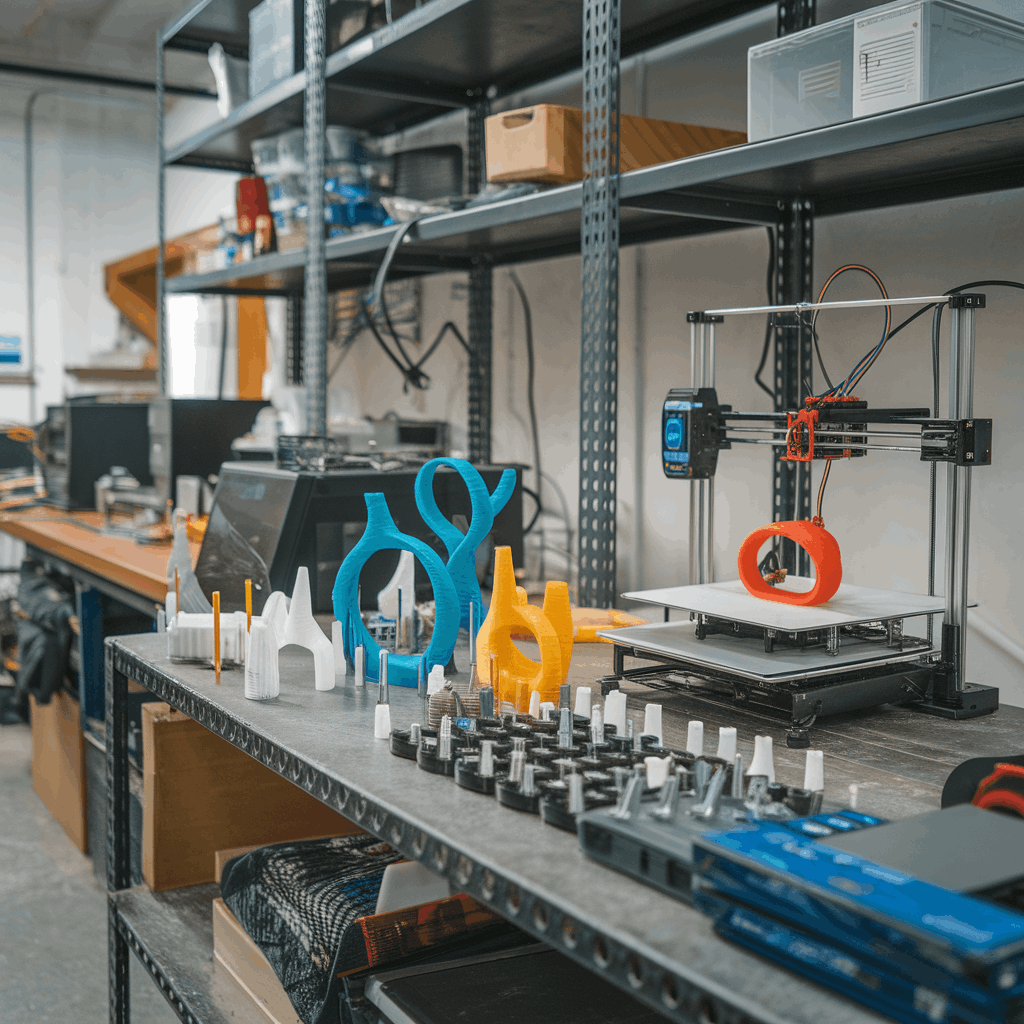

Production of 3D Printing Supports, Filaments, and Hardened Nozzles

We manufacture precision parts and consumables for additive manufacturing teams in Malaysia and the region. From custom breakaway supports to engineered filaments and ultra‑hard nozzles, our components are built for uptime.

Lead times from 3 business days • MOQ flexible • ISO‑minded QA

About Incubuyemo Additive Components

Founded by process engineers and materials scientists, we supply parts and consumables for FDM/FFF, pellet extrusion, and hybrid manufacturing lines. We operate out of Kuala Lumpur with regional distribution partners in Penang and Johor.

Batch IDs, incoming resin checks, and dimensional sampling are standard. We retain samples for 12 months for every production run.

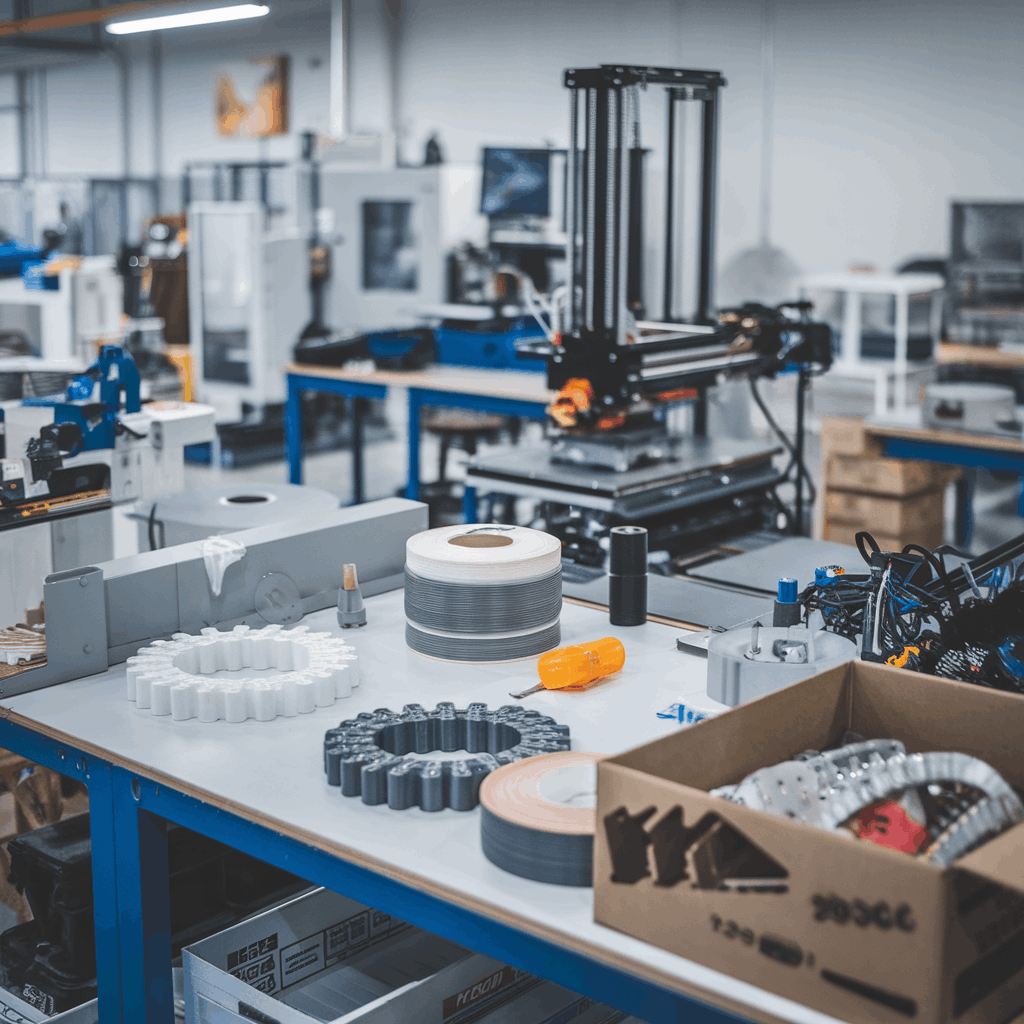

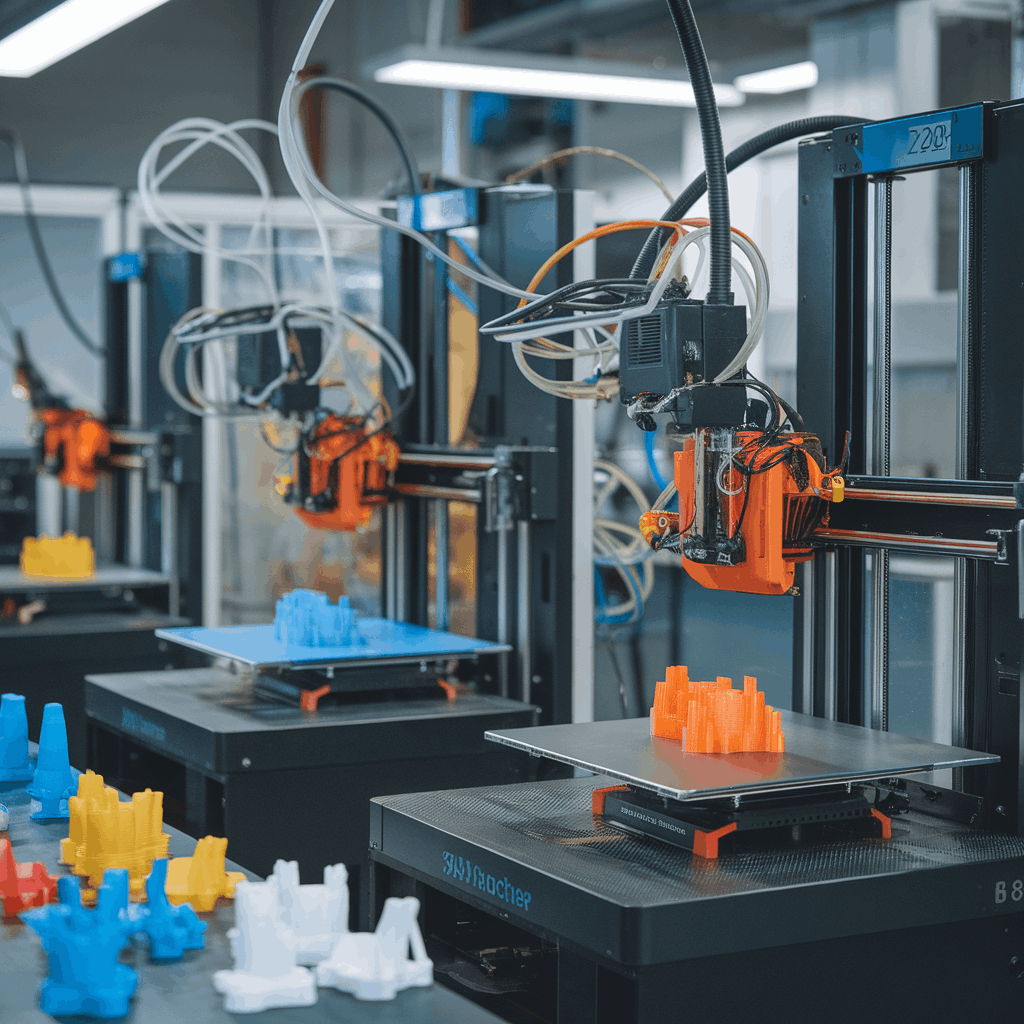

Dedicated lines for support materials and high‑temp filaments ensure consistent output. We build to forecast and can hold buffer stock.

From PLA+ to carbon‑filled nylon and PEEK blends, our compounding partners allow rapid trials and consistent extrusion profiles.

Components We Produce

Our portfolio covers high‑mix, low‑to‑mid volume components for demanding additive teams.

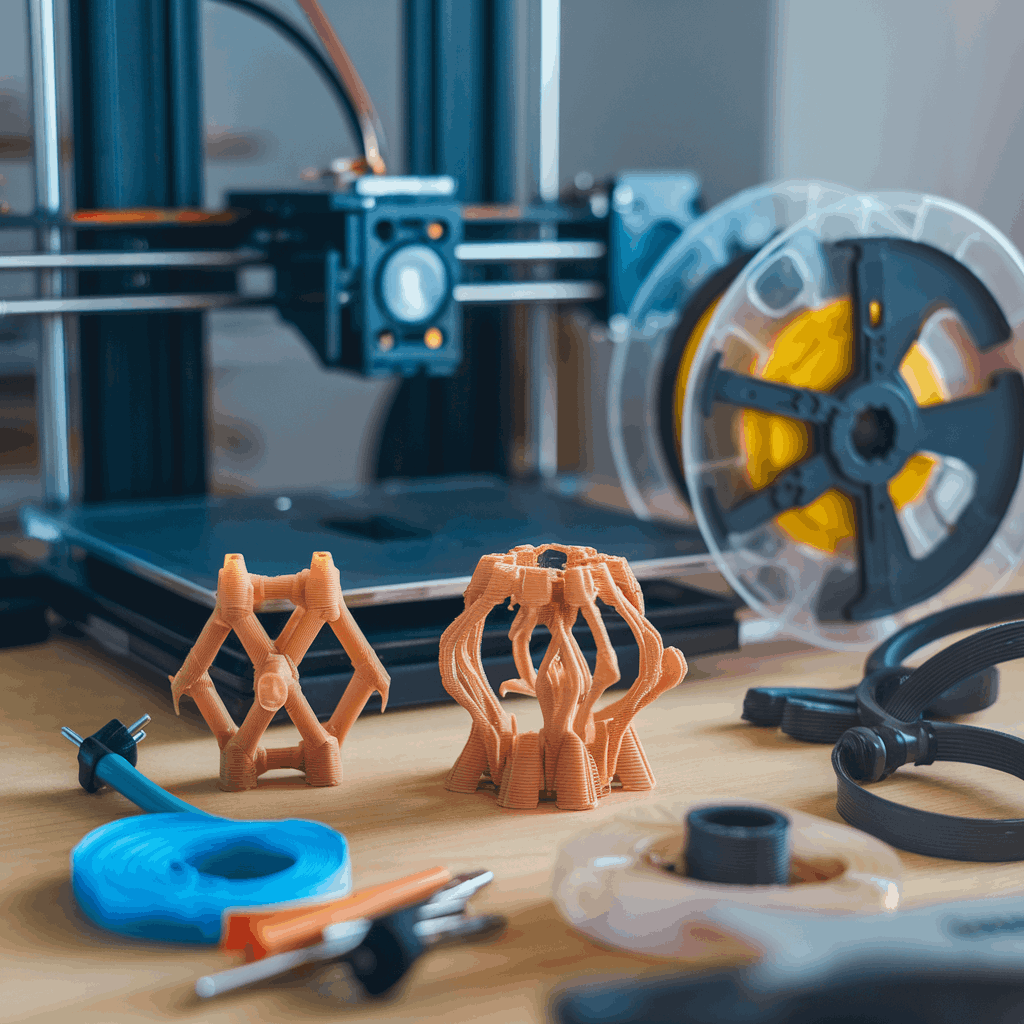

Support Materials

Breakaway and soluble supports tuned to your base material and chamber temperatures. Custom diameters available.

- 2.85mm and 1.75mm

- Low‑moisture packaging

- Material compatibility charts

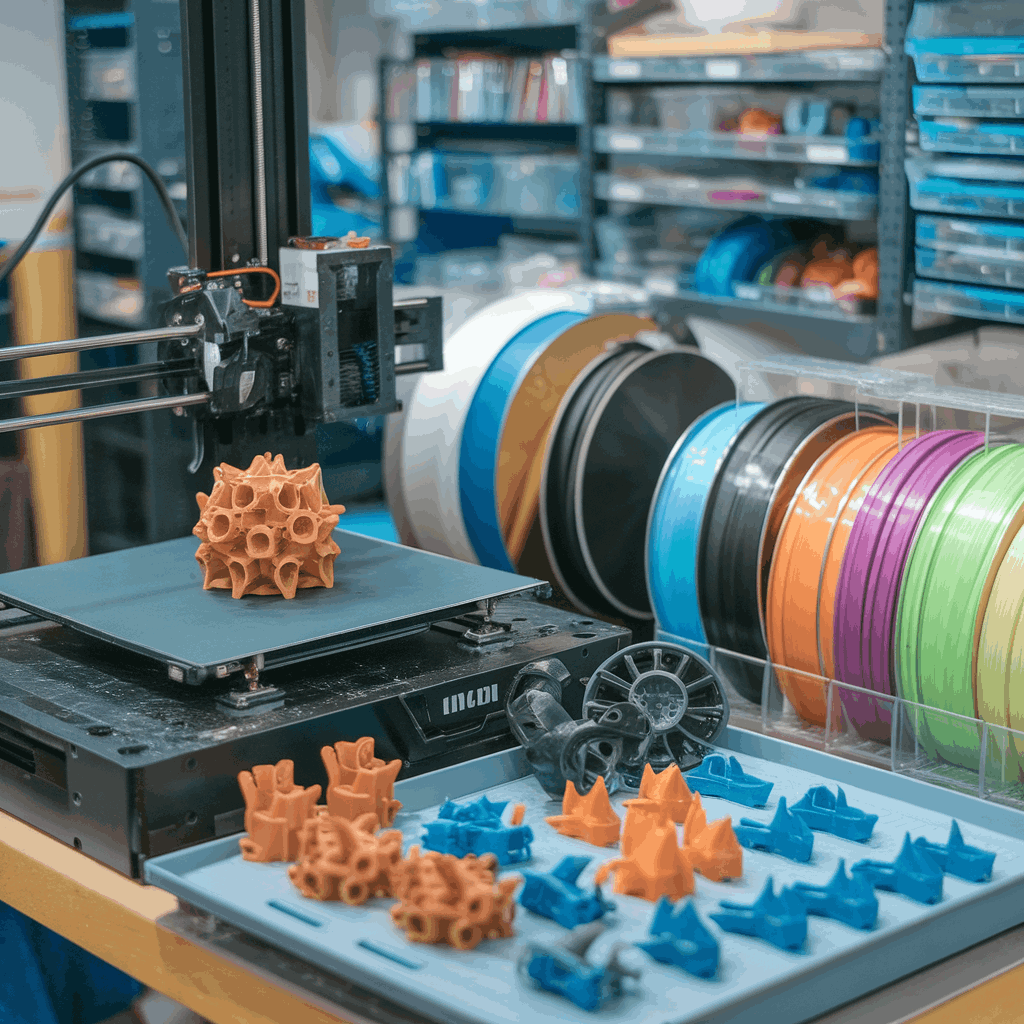

Engineered Filaments

PLA+, PETG‑CF, ABS‑ESD, PA12‑CF, and high‑temp blends for production jigs and short‑run end‑use parts.

- Tight ±0.03 mm tolerance

- COA and MFI data per batch

- Spools: 750 g / 1 kg / 2.5 kg

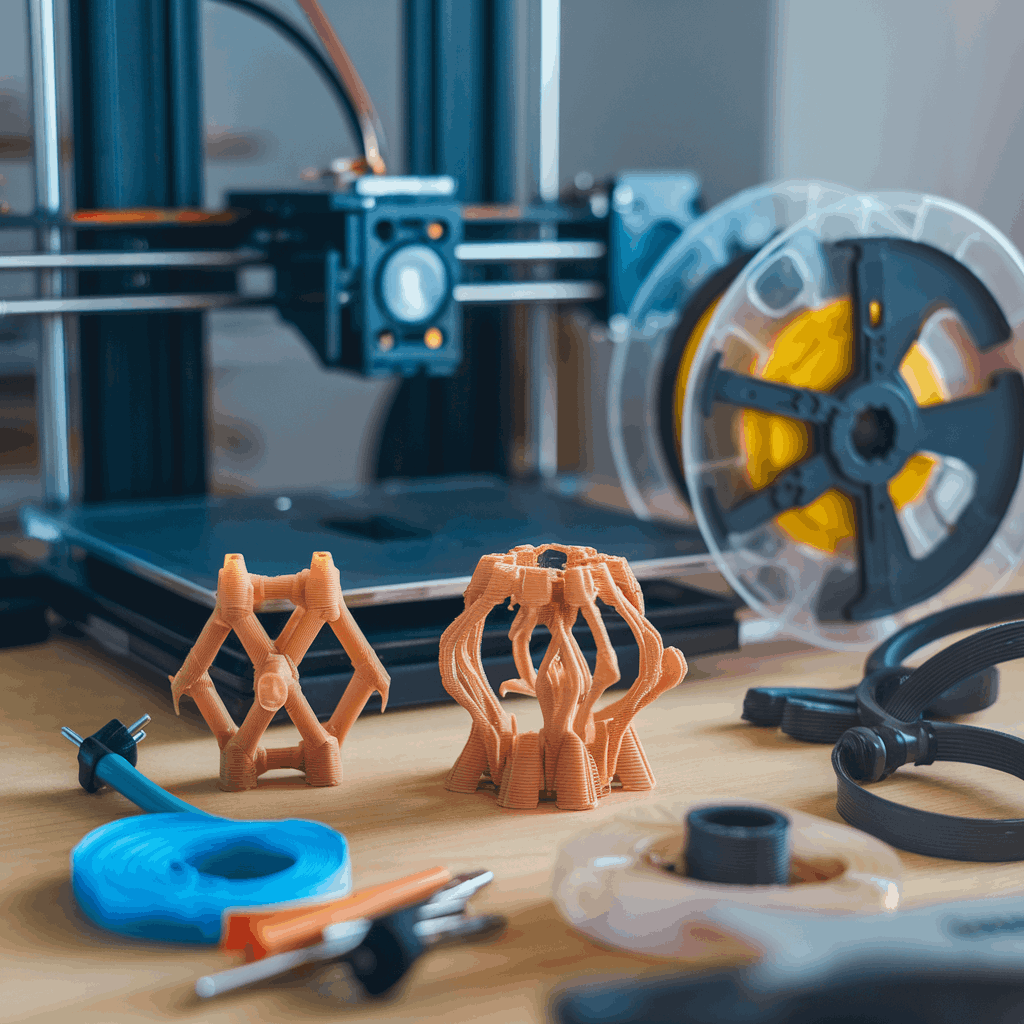

Hardened Nozzles

Wear‑resistant nozzles in A2 tool steel, hardened copper alloys, and ruby‑tipped options for abrasive filaments.

- Sizes: 0.2–1.0 mm or custom

- Nickel/PTFE plating

- Thermal response tested

How We Work

A simple, measured approach that respects engineering schedules.

Use case, equipment, material constraints, and monthly demand.

Sample kits and test spools; adjust diameters and moisture spec.

QA gates, documentation, and pilot delivery with COA.

Forecast‑based manufacturing with buffer stock options.

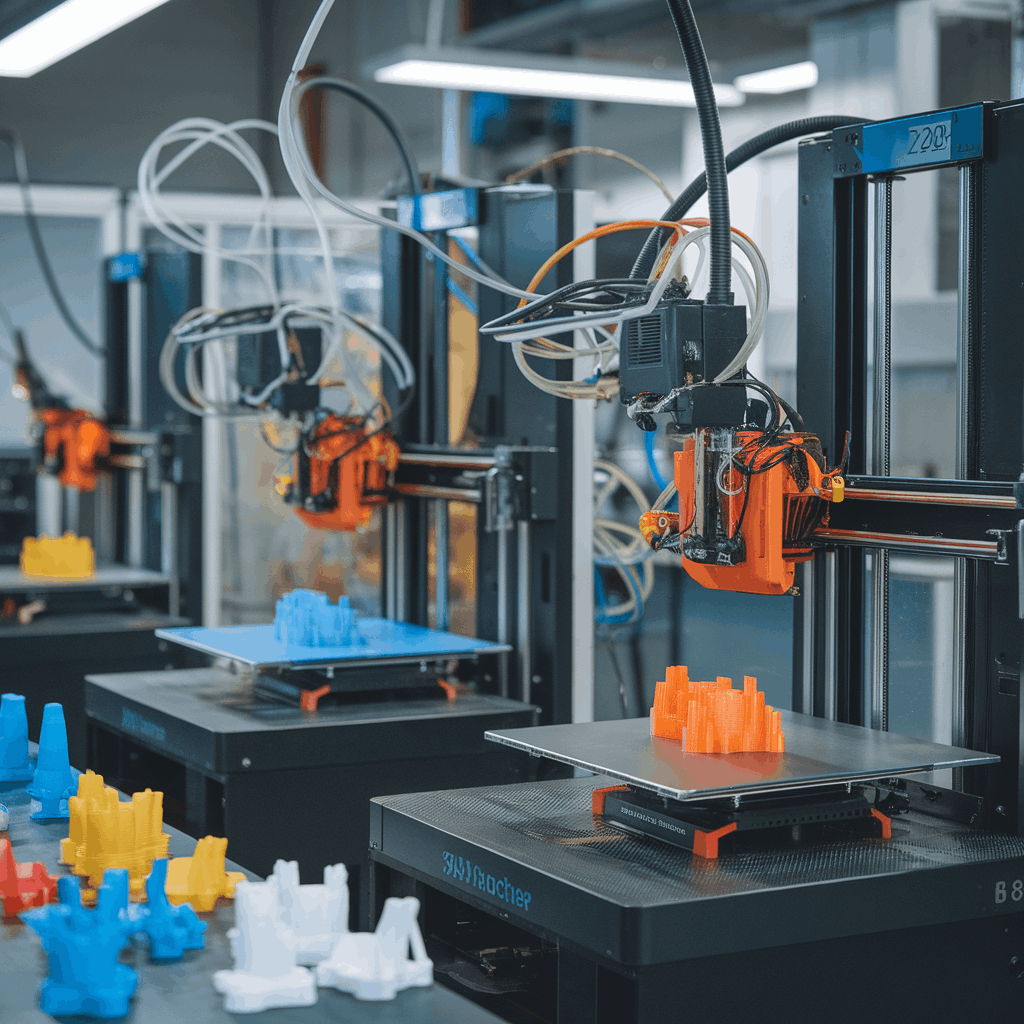

Case Studies

Selected wins from customers in ESD tooling, automotive service parts, and EMS jigs.

Electronics EMS

Switched to ABS‑ESD + hardened nozzles for stable throughput.

−31% downtime from nozzle wear.

Auto Service Parts

Carbon‑filled nylon fixtures; double‑sealed spools for humidity.

+18% dimensional yield across batches.

Tooling Supports

Custom 2.85mm supports optimised for chamber temp profiles.

−22% print time with tuned breakaway.

Pricing & MOQs

Transparent tiers with pilot‑friendly minimums. All prices in MYR; export terms available.

Support Materials

RM 85 / kg · MOQ 10 kg

- Custom diameters on request

- Moisture spec ≤ 0.2%

- Lead time from 5 days

Engineered Filaments

RM 95–240 / kg · MOQ 25 kg

- ±0.03 mm tolerance

- COA included

- Volume pricing above 100 kg

Hardened Nozzles

RM 45–180 / unit · MOQ 50

- Tool steel / copper alloys

- Nickel/PTFE options

- Custom bore sizes

FAQ

Yes. We issue batch COAs and retain witness samples for 12 months.

We can run pilots from 10 kg upwards with rapid iteration on diameter and additives.

Peninsular Malaysia next‑day courier for stocked items; East Malaysia and Singapore in 2–4 days.